What is recycling according to Wikipedia?

Wikipedia mentions recycling as a key component of modern waste reduction. It also states that recycling is a process where we change waste products into new products. This helps prevent waste of useful materials.

There are clear evidences dating to as far as 400 BC state examples of recycling. Recycling provides so many advantages and savings over using new materials.

Why is recycling important?

By recycling, we extend the life and usefulness of a product which has already made to use. By recycling any product which is of no use can be converted to something which can be valuable and something which can be use again and again.

Recycling helps reduce consumption of fresh raw materials, reducing energy usage, and helps in reducing pollution.

Recycling in asphalt industry – some facts.

As we see the advantages of recycling and acceptance of the same in the asphalt industry has been wide. It is time before people start understanding the advantages of RAP with respect to our environment.

As we see the advantages of recycling and acceptance of the same in the asphalt industry has been wide. It is time before people start understanding the advantages of RAP with respect to our environment.

Recycling made possible by asphalt plants by Atlas

It is notable fact that when hot mix asphalt is recycled, the ingredients present like the aggregates and bitumen are as good as new. So it is very advantageous using this material. This material is cost effective, environmentally safe and also as good as new.

Cost effective because when we add a certain percentage of RAP (eg. 30%) in the hot mix plant, we save on the cost of raw aggregates and also binder material which would have been used if that 30% would have been created from new material.

Environmentally safe because we need not add any harmful chemicals or additives for processing RAP. Less energy is consumed in preparation here.

As good as new because the aggregates and bitumen present in recycled asphalt pavement when reused with virgin material glues itself with the new material and becomes a part of the new material.

Atlas has always made efforts to implement addition of reclaimed asphalt pavement (RAP) material into its asphalt plants.

Our list of product includes:

- Asphalt batch mix plant

- Asphalt drum mix plant

- Counter flow asphalt plant

Out of the above mentioned products the products that can allow addition of RAP are batch mix plant and counter flow drum mix plant.

Asphalt batch mix plant with RAP:

This equipment is considered to be the best technology as far as making hot mix asphalt is considered. It applies the most accurate technology and process to make HMA in batch. RAP is introduced directly into the mixing unit of the batch plant after weighing.

Counterflow asphalt plant with RAP:

Double drum plant:

We manufacture and offer counter-flow asphalt mixing plant for sale. These plants offer drying and mixing in separate compartments. Both the compartments are drums which are equipped with flights inside and the rotation of the same helps in efficient heating and then mixing. The first drum is for heating the aggregates by use of counterflow technology. The aggregates enter the drum from one end of the drum and move towards the other end of the drum. The other end of the drum is equipped with a burner for heating the aggregates. As the aggregates exit the other end of the drum, their temperature is elevated making it ideal for mixing. As the aggregates enter the second drum, they get mixed with bitumen and filler material.

Single drum plant with mixer:

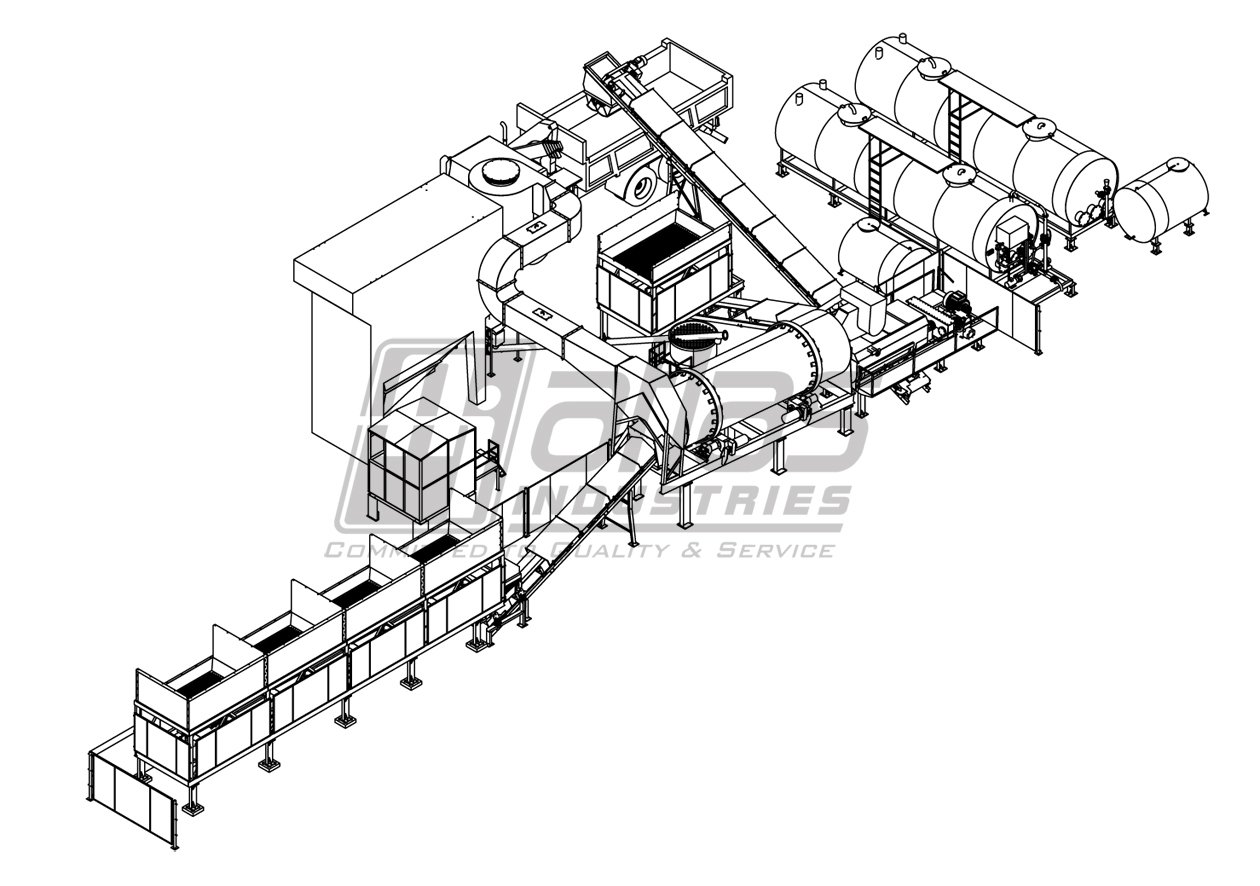

Instead of double drum counter flow plant, customers can also opt for single drum plant with a pug mill mixer for mixing. Such plants are commonly seen in Europe and they take up less space for installation. We have exported one such plant in Spain with provision to add RAP directly in the mixing unit.

As you can see in the layout, these plants come with a drum featuring counter-flow technology for drying the aggregates and for mixing the aggregates there is a mixer. The operations are same like the double drum plant except that here we have a mixer for mixing instead of a drum.

Single drum plant:

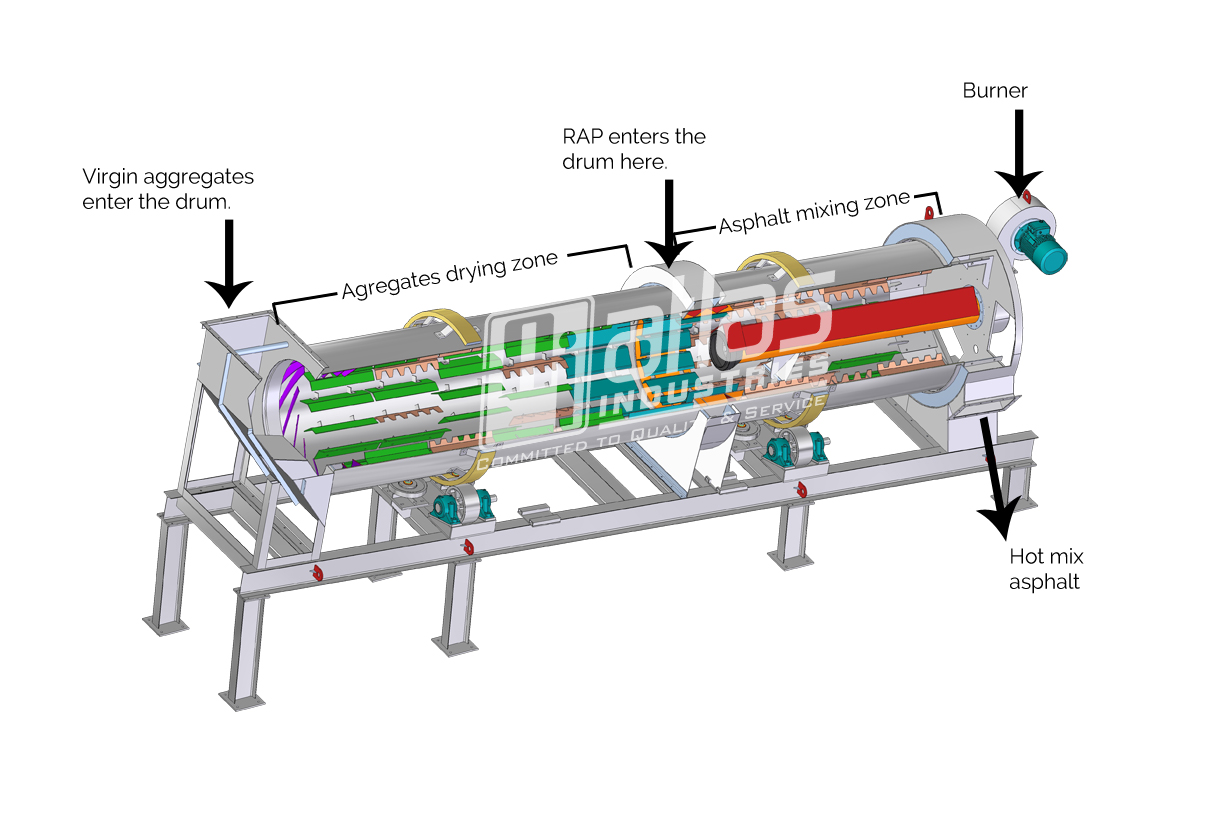

In addition to the above types, we have recently developed single drum type counterflow asphalt plant for addition for recycled asphalt pavement. Here the plant operation of drying and mixing is limited inside a single drum. The aggregates enter the elevated part of the drum and move towards the other end of the drum as the drum rotates. The aggregates inside the drum are treated to the burner flame in a counterflow manner. Here the burner flame starts from the center of the drum to the opposite end of the aggregates entry. This is different from the double drum plant where the burner flame starts from the other end of the drum. The aggregates are continuously moving towards the other end of the drum even after treated with the burner flame. Just behind the burner flame, there is RAP collar on the drum which allows addition of reclaimed asphalt pavement (RAP) in the drum. As the RAP enters the drum just behind the burner, it gets in contact with the hot aggregates. Since the temperature of the heated aggregates is already high, it helps to melt the binding material in the RAP and bind it with the virgin aggregates and binder material which enters the drum from behind the burner flame. When RAP enters the drum it is already being weighed and its flow is controlled as required from inside the control room.

How is this equipment different from other counter-flow plants?

This equipment is different from the other continuous asphalt mixing plants that offer addition of RAP because it offers drying and mixing in a single drum. This makes this equipment very compact and fuel efficient.

How does this machine solve your problem?

This machine can be useful for you if your problem(s) are listed below:

- Site space is limited.

- You are always looking for fuel savings methods or tricks for your plant.

- Want to shift sites frequently without getting into hazzles of setting the two drums or setting the mixing unit.

- Recycling is important for you.

Advantages of Counterflow Asphalt Plant design are as below:

- Less space required.

- No hazzles in foundation as there is only one drum for both the operations.

- Minimum heat loss compared to single drum with mixer and double drum plants.

- Less dust emissions.

- Add reclaimed asphalt pavement directly behind the burner flame at a point where the aggregates temperature is very good for mixing.

- Saves fuel compared to other designs.

Conclusion:

If your requirement is counterflow plant with separate drying and mixing one or single drum counterflow asphalt mixer Atlas has it all Contact us to know more (click here).