Atlas manufactures of quality mobile concrete plant in India. This equipment offered for sale comes in capacities 20 m3/hr., 30 m3/hr., 45 m3/hr. and 60 m3/hr. These concrete batching plant are on a single chassis and come with advanced twin shaft mixer for superior mixing.

Atlas has designed RMC plants on a rugged structure keeping in mind the rough Indian operating conditions of equipment. The compact concrete plant by Atlas ensures that the plant required least space, yet the concrete production is not compromised. Installation of the mobile concrete mixer is quick. It can be done in 2-3 days with less foundation requirement making this concrete plant. Truly mobile and time saving for the customer.

To save space and the plant comes with fordable cabin with PLC panel inside. King pin attachment is there for quick attachment with the trailor. An option to go for pneumatic braking also available with the offered concrete batching plant. Atlas is among the few concrete batching plant manufacturers from India who do not compromise on the quality. Direct discharge of concrete into transit mixer or concrete pump is also possible.

Advantages of mobile concrete plant are as below

The mobility factor of this concrete plant drives customers towards it. Simple and productive design is the main highlight of this machine. We have designed this concrete mixing plant with the end user in mind. All the maintenance points are well considered and laid out. The simple design coupled with a strong mixing unit makes this an ideal package for civil construction jobs. This machine has been installed in many countries like Myanmar, Nigeria, Philippines, Bhutan, Cameroon, etc.

Aggregates can be fed into the 2 x 2 bin feeder from one side. Weighing of the aggregates is done by a gathering cum charging conveyor which is suspended on four load cells. After individual weighing of aggregates, this conveyor takes the aggregates to the twin shaft type mixing unit of concrete batch plant. The plant comes prewired with junction box. Air compressor is on the chassis to maximize mobility. Weighing of water, cement, fly ash and additives is in individual compartments above the twin shaft mixer.

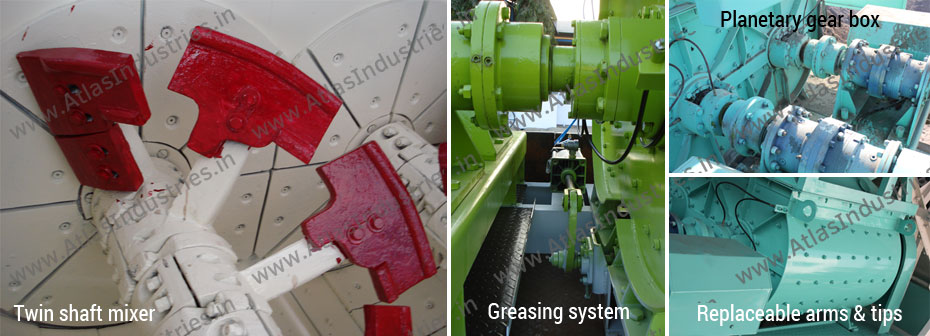

Twin shaft mixers:

Twin shaft mixers with Atlas concrete batch mixer come fitted with anti-wear liners and with planetary gear boxes. The paddles are of cast iron and mixing occurs so that optimized mixing of concrete seen. These paddles are bolted into the mixing arms. Mixing arms are bolted into the shafts for better maintenance and durability of the shafts. These mixing shafts have roller bearings and seals on both the sides. Twin shaft mixer is designed to ensure reliability and reduced service with maintenance costs. The planetary gear boxes driven by electric motors are for long life of the concrete plant. Bearings are installed on a separate housing. Also Isolated thus protecting them in case of seal failure. Inspection platform with stairs is provided with the plant for easy maintenance and cleaning of the twin shaft mixer which comes with water jet cleaning system and single point greasing system.

Our panel is PLC touch screen type with data backup facility in pen drive and upto 99 recipe storage available. An optional printer can be provided. The calibration process of the panel is very easy.

Optional SCADA panel can also be supplied with concrete mix plant.

Optional 18 Tons cement / fly as storage silo available. Standard concrete plant comes with cement hopper and screw conveyor.