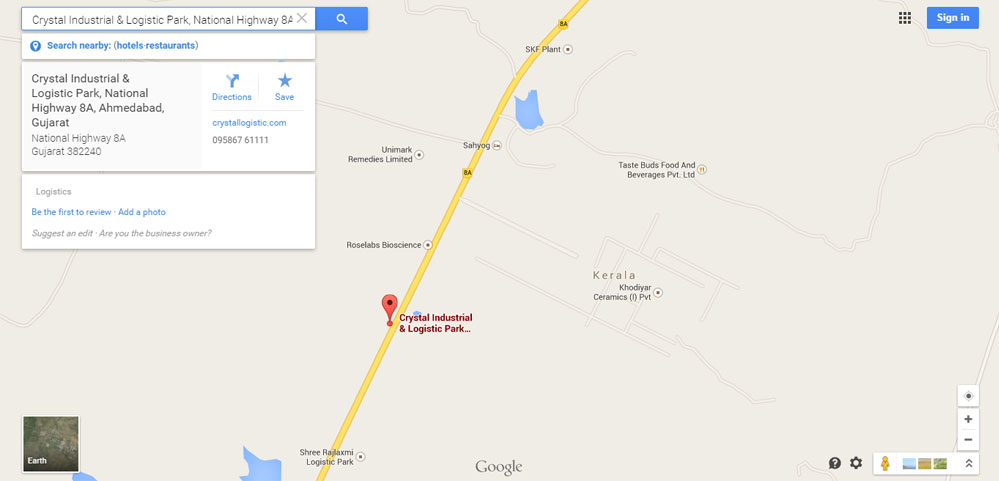

The traveling time from Ahmedabad to the Portable Concrete Plant was not much as the location of the site was near. The plant which we sold to the customer has installed it at an industrial park which is on the Ahmadabad-Rajkot highway. The distance from the nearest town Ahmedabad is 42 kms (Bhayla village) and with medium traffic one can reach the Crystal Industrial and Logistic park in 45-60 min. This machine will be doing concrete roads and concrete flooring at the industrial park.

I has spoken with the customer a day before and informed him that I will be visiting the place to take some pictures and video of the plant. I was told that the equipment will be started at 9 am and will run continuously till 1 pm and it was up to me to reach the place anytime.

I left Ahmedabad for the place at 7:30 am so that I would be able to catch a glimpse of the plant when the sun is not above the head and take some good snaps. But I managed to reach at around 8:15 am thanks to traffic. When I reached there I was greeted by a very kind man at the gate of the industrial park and he was very happy to guide me. It is really very nice to see humble human beings treating each one with respect even when he sits in a dusty cabin all thought the day.

Portable concrete mixer

Early morning the operator was busy with laying bricks below the control cabin of the portable concrete plant. He was stuffing the bottom with mud so that the cabin is protected with dust. I asked him why did you opt for the concrete mixer without cabin. You could have bought this equipment with a cabin from Atlas. But then I learned that the cabin they got was inexpensive compared to the one we offered. Good Indian way of saving wherever possible. When I closely looked at the cabin, it was not finely welded, the plates were thin and was not firmly secured on the ground by proper foundation. I then discussed that during monsoon this cabin will need to be covered. Usually the panel offered is with a dust proof cover but it is good if we keep the control panel secured inside the cabin. This helps to protect the cabin of the portable concrete mixer and elongates its life.

Moving around the equipment and taking the view of the operator satisfied me as he was very happy using the plant since the last two months without any problems. It was already past 9 and I was getting impatient to get the ready mix concrete plant started and take video to my satisfaction. But then there was a small problem, a dumper full of rocks got stuck in mud while taking a turn and all this happened just near the machine. Despite several attempts the vehicle was not able to move and in fact got stuck more in the mud. Then came a back hoe loader to the rescue but then it was no match for the mighty mud. Finally they decided to empty some contents and try and this method succeeded.

Meanwhile the customer and his brother had arrived to the site and straight way they went to inspect the concrete road inside the premises which was recently done. After some time they came to the plant and asked to start the same without any delay. This was the moment of joy as I was very eager to see one of our portable concrete plants working.

The video was done in quick time without wasting any moment and the video is live on youtube. Watch below:

As one can see the machine is equipped with a reversible drum mixer which is like a transit mixer mixing in clockwise direction and discharging when it moves in anti clockwise direction. The feeder bins are adequately sized and 2 x 2 type so that the portability factor of the machine is retained. There is a conveyor below the aggregate feeder which is suspended on four load cells. This conveyor gets the aggregates and sand onto the charging conveyor after weighing and the charging conveyor takes the same into the mixer. There is facility for weighing and addition of water in the equipment and also for additive. There is a separate hopper for cement storage and cement from bags is stored into the cement hopper only to be transferred to the cement weigh hopper by means of a cement screw conveyor. The control panel provided by Atlas is PLC type with a 7” touch screen colour display making the operation user friendly. Air compressor sits quietly on the plant chassis without taking up any extra space.

See photos of the plant on our website, click here

Last conversation with the customer revealed that they are planning to set up cement silos so that they do not waste money on labour.

Conclusion:

A nice trip to the site was even bettered with so much positive response from the plant owner and operator for the machine. Such feedbacks always motivate us to do better and give our best each time to this industry.