Asphalt plant is equipment that is designed to produce hot mix asphalt. It uses aggregates, sand, bitumen and filler material in specific proportions to produce HMA also known as asphalt concrete or black top. The main feature of an asphalt mixing plant is that it will heat aggregates and then mix them with bitumen and other adhesive substances to prepare hot mix asphalt which is a paving material. Aggregate here can be a single sized material or it can be combination of various materials of different sizes with a combination of fine and coarse particles with or without addition of a filler unit.

Types of hot mix plants

There are two basic types of hot mix plants available in the market today batch mix plants and drum mix plants. If we talk about any plant it will fulfill the basic purpose of producing HMA. The key difference will be in the operation of each type of asphalt plants. Depending on the choice of buyer the asphalt mixers can be stationary type or portable type.

-

Batch Mix Plant

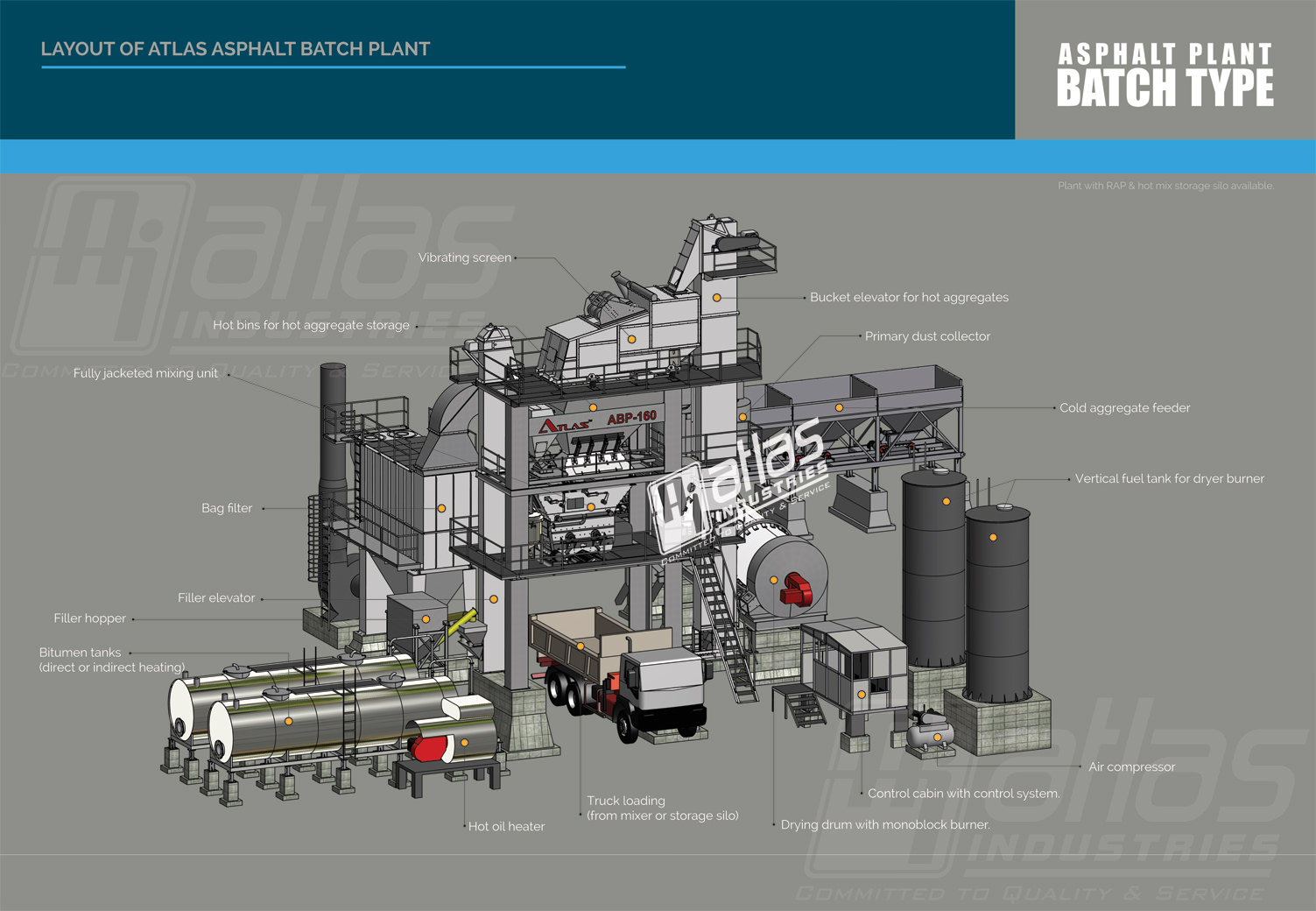

The asphalt concrete batch mix plant consists of a number of components.

The first component is the cold aggregate feeder bins where the aggregates are stored/fed in separate components as per their sizes. There are auxiliary feeder belts below each bin and gathering conveyor that runs below all the bins. This conveyor will transfer all the aggregates to another inclined conveyor belt that will take all the materials into the drying drum. Before the materials are transferred to the inclined conveyor belt, they aggregates have to pass through vibrating screen so that oversize materials are removed.

The next component is the drying drum. It is fitted with a burner unit for moisture removal and heating of aggregates are carried out to achieve proper mixing temperature. These aggregates are them carried to the top of the tower unit by an elevator.

The tower unit consists of 3 main units: vibrating screen on top then we have the hot bins and mixing unit is below the hot bins. As the aggregates are carried to the top of the tower unit, they are made to pass through the multi deck vibrating screen (usually four screens are there) so that aggregates are separated as per their sizes. After separation they are temporarily stored in different compartments called as hot bins. This section of hot bins is just below the screening unit. Hot bins will store the aggregates in individual bins and then release the same into the mixing unit below as per the weight set in the control panel. At the time when aggregates are weighed and released into the mixing unit, bitumen and optional mineral filler is also weighed and released into the mixing unit. After proper mixing, the mixture is released into waiting trucks of into the storage silo.

For environmental protection, air pollution control devices are equipped. These devices in most of the cases are bag filter units. The fines are made to pass through the bags present in the bag filter and the dust is trapped by the bags. This dust collected can also be reintroduced into the aggregate elevator.

-

Drum Mix Asphalt Plant

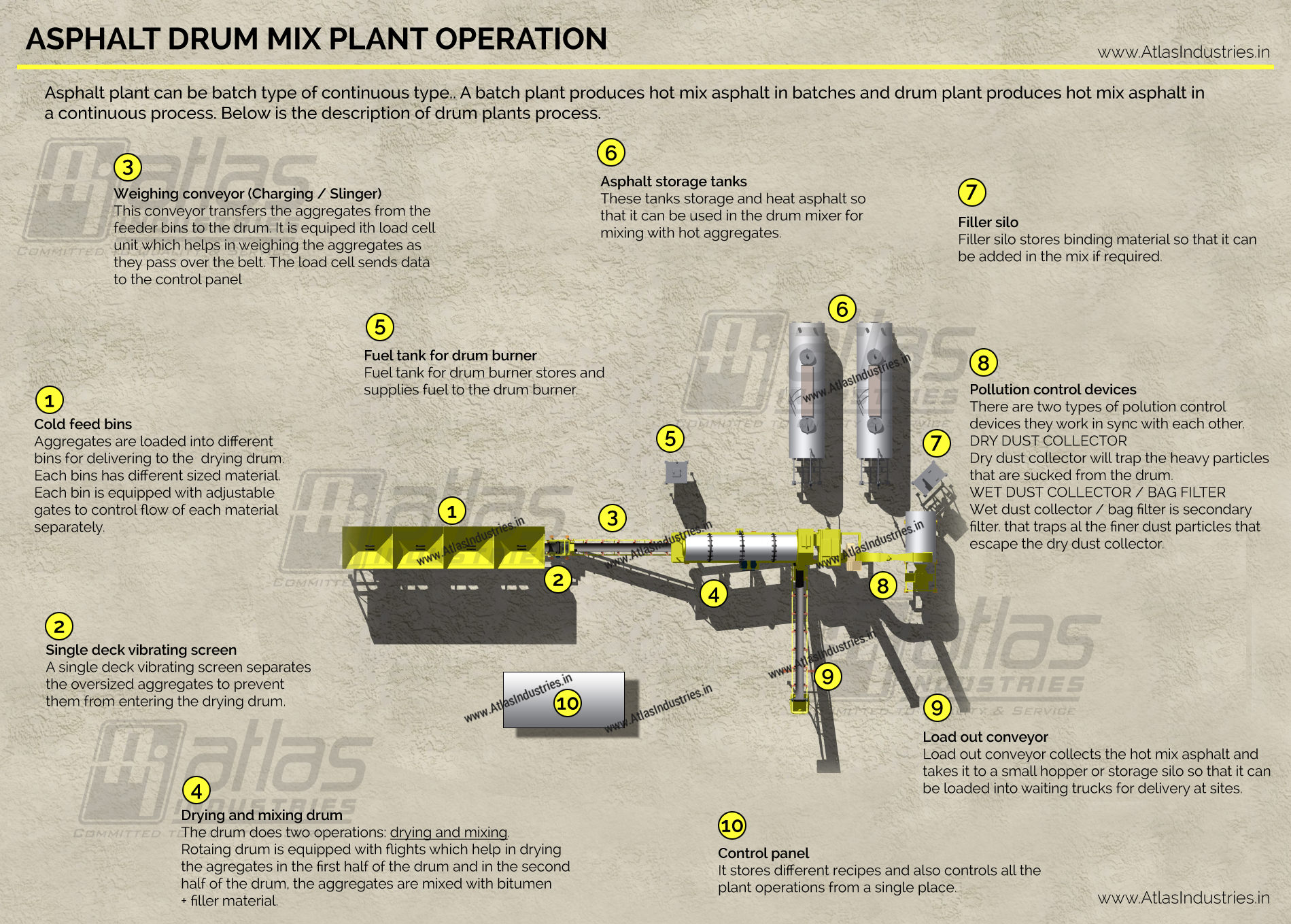

The cold bins are the same in asphalt drum mixers like in batching plants. The process here is also the same till the aggregates enters the drum unit by passing through the vibrating screen. The drum here serves two purposes – that of drying and mixing.

The first half of the drum is for heating the aggregates and in the second half mixing with bitumen and filler material takes place. Since this is a continuous mixing plant, a small sized hopper for temporary holding the HMA is provided. Bitumen is stored in separate tanks and it is added into the second part of the drum. For pollution control, wet scrubber or bag filters are provided with the asphalt plant. To get in touch with us call +91 97238 10565 or write to contact@atlasindustries.in.