Atlas Asphalt batch mix plants are known for carrying jobs with precision. Mobile Asphalt Plants are the ultimate equipment for road construction and best piece of machinery for any company. Asphalt Batch Plants are available in capacities 80 tph, 120 tph and 160 tph. Atlas are trying to meet the needs and demands of the modern contractor.

What are the factors that make the batching plant ideal choice for most road contractors?

The main and foremost important factor is the ability of this Asphalt batching plant to weigh each and every material as per their size and mix them in required proportions.

This facility provided by the equipment is very good because one can actually control each and every ingredient and make the recipe as required. In any given recipe of hot mix plant the basic ingredients are bitumen, filler material / additive / lime, aggregates and sand. The size of aggregates will vary depending on the surface to be laid. If more sand is required to be added or more aggregates of the sizes 10-20 mm are required, this machine can do it all. Right in the control panel there are options to set the proportions of aggregates that we want to add in the mix material. The control panel gives instructions to the different components to get desired results.

How is the capacity of asphalt plant batch type calculated?

The capacity of batch asphalt plants is mainly dependent on the size and number of the batches that it makes in one hour. Since this is a batch type machine it will make hot mix asphalt in batches and not in a continuous process like a drum mixer.

80 tph small asphalt plant has a Mini asphalt mixer of capacity 1000 kgs. This 1000 kgs is the size of one batch. In one hour this plant will complete 80 cycles or say 80 batches. When we multiply the size of one batch by the number of batches completed in one hour we get the per hour production capacity of that plant.

What are the factors that affect the production of Asphalt batching plant?

There are many factors that affect the production of asphalt batch plant like: aggregate moisture content, bulk density of aggregates, percentage of dust in the mix, ambient temperature, mix temperature and altitude.

When the moisture content in aggregates is 3% or less then it does not affect the production. When the moisture content is more than 3% say 4% it will affect the production by 12% and you can expect the production to be around 88%. When the moisture content is at 5% the production will be 75% and when the moisture content is 7% the production will be down to 50%.Hence we can easily say that as the moisture content increases, the production drops.

Same thing can also be said about percentage of dust in the mix. If the dust percentage is 50% then the production will be affected by 6%. When it is 60% in the mix then the production will go down by 12% and when the dust is 70% the production will go down by 18%. Hence it can be said that as the dust percentage increases, the production of the hot mix plant drops.

Ideally the plant is designed to operate and perform at mix temperature of 150 degree Celsius. When the temperature requirement of final hot mix material is more than 150 degree Celsius – say 160 degree Celsius, the plant will perform at 95% capacity. When it is 170 degree Celsius, the plant will perform at 90% of its full capacity and similarly at 180 degree Celsius, the plant will perform at 85%. Hence it can be said that as the temperature of hot mix material is increased it has an effect on the production of the equipment.

When we compare output of the plant with altitude, the output decreases once the plant is placed at a height. If the plant is placed at 0.5 kms above ground level, the capacity will go down by 6% and when the plant is at 1.5 kms from ground level, the capacity will go down by 18%.

The variations are all specific to a particular character, when two or more factors are combined it can have additional effect on the production of the asphalt batch mix plant.

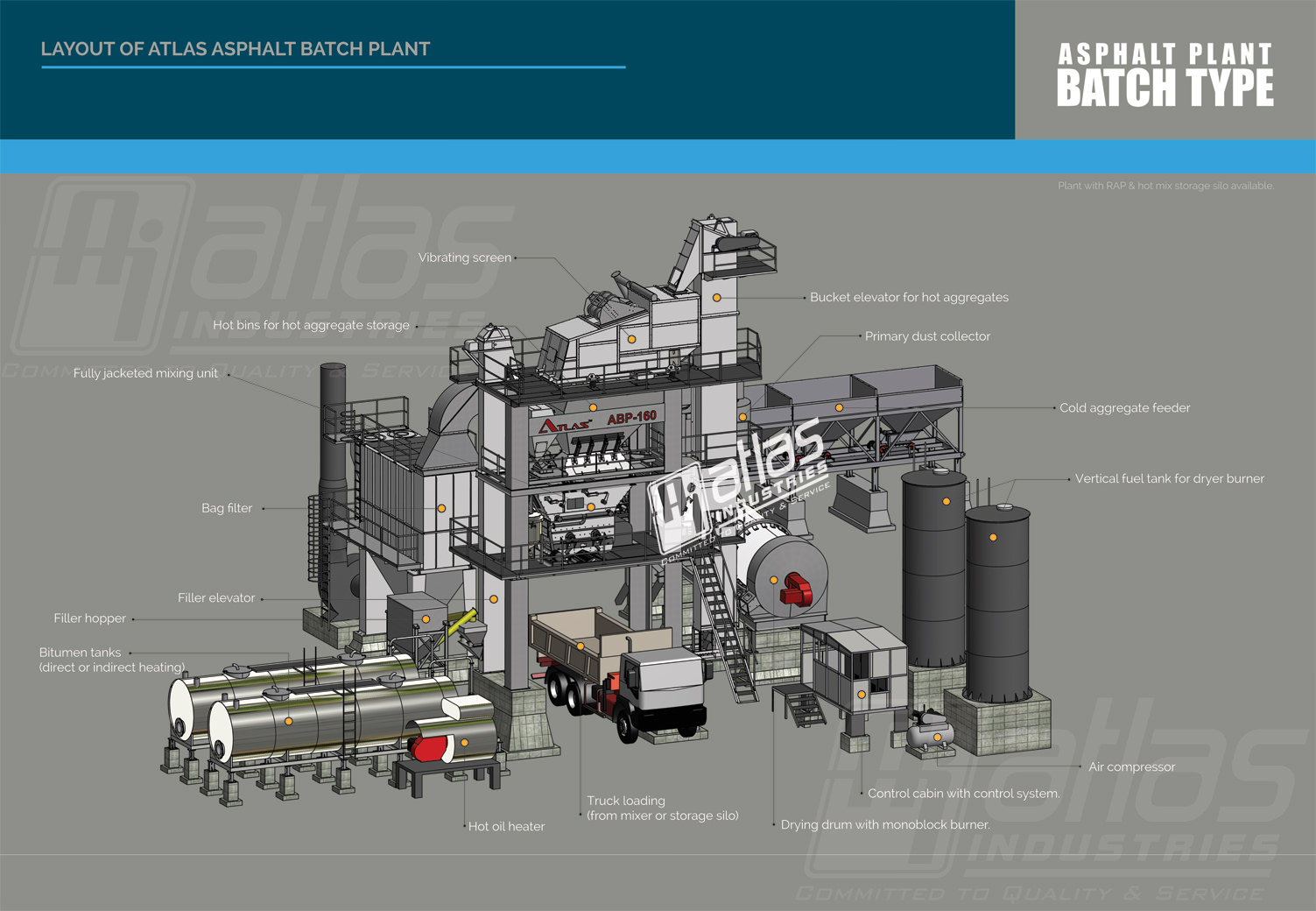

What are the main components of asphalt mixing plant?

There are many components that work in unison to make this plant complete. The feeder bins, dryer drums, filters for environment protection, tower unit, control panel, etc. Each component is discussed in details below.

- Cold aggregate feeders: Cold aggregate feeders are the starting point for any batch process of the plant. They will hold the cold and virgin aggregates in separate bins according to their sizes. Different aggregate sizes have to be in separate bins because they will be controlled by the frequency controlled drives.

- Charging conveyor and vibrating screen: Vibrating screen here is a single deck primary scalping screen designed for removal of oversized aggregates. As the aggregates pass through the screen it helps in separating the bigger particles from the rest.From below the screen a conveyor runs straight to the drying drum. This conveyor takes the aggregates from below the vibrating screen and transfers the same to the drying drum.

- Burner and drying drum: This drum uses counterflow technique to heat the aggregates and helps remove moisture content. Atlas is one of quality asphalt plant manufacturers who take immense care in manufacturing of this critical part. The drum is insulated from all sides to prevent heat loss and maintain a healthy temperature inside the drum. This also ensures that the burner fuel consumption is low. Burner is a mono-block unit which is very compact yet efficient unit. The design of the drying drum flights coupled with the efficient burner makes this drying and mixing drum very efficient. The burner is low noise system designed for optimum performance even in harsh conditions.

- Pollution control devices: As responsible asphalt mixing plant manufacturers from India we supply this equipment with primary and secondary pollution control devices as a part of standard package. Pollution control devices include dry dust collector and wet dust collectors. Dry dust collectors will trap the heavy dust particles sucked straight from the drying drum and treat them to cyclonic effect to settle them. Behind the dry dust collectors we have the bag filter system or wet dust collectors. The bag filters will take care of the lighter dust particles and treat them so that the environment is safe. Bag filters allow passing of the sucked air from the bags just to ensure that the dust particles get trapped in the bags. On the other hand, the wet dust collectors use water to trap the dust particles and prevent them from escaping.

- Bitumen tanks: Leading asphalt plant manufacturers will always put emphasis on supplying sufficient storage for bitumen for the equipment. The bitumen tanks are insulated and have heating system. Heating of bitumen can be done directly or indirectly. In case of direct heating, the tanks are equipped with burners. In case of indirect heating, the heating is done with the help of hot oil circulating through the pipes that pass from inside the bitumen tanks. The heat from the hot oil is transferred to the bitumen which helps in melting bitumen.

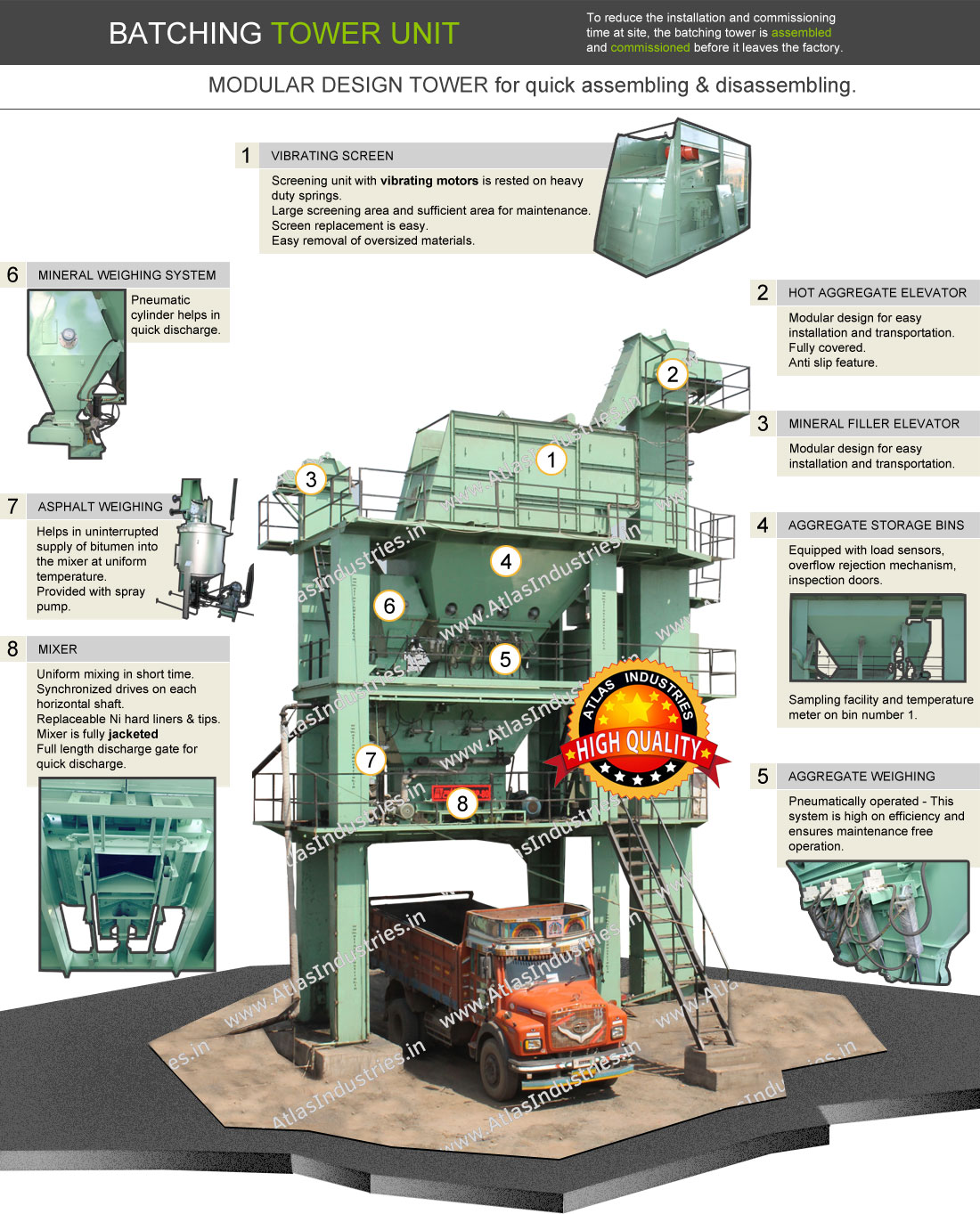

Tower unit:The tower unit consists of three main components like the vibrating screen, hot bins and the mixing unit.

Tower unit:The tower unit consists of three main components like the vibrating screen, hot bins and the mixing unit.- Vibrating screen: This unit stands on top of the tower unit. Vibrating screen receives the aggregates from the drying drum by means of a fully covered bucket elevator. Vibrating screen helps removal of oversized material by effectively and fast screening of the aggregates.

- Hot bins: Hot bins will store the separated aggregates into separate compartments after the screening process takes place. Apart from the storage factor, the hot bins will allow separate weighing of aggregates as per the requirement form the set recipe. Aggregate discharge is pneumatically operated which is a maintenance factor. Just near the hot bins there is a mineral weighing hopper. This hopper weighs the required minerals and transfers the same to the mixing unit.

- Mixing unit: Any serious asphalt mixing plant manufacturers will consider making this unit a very maintenance free device. The Asphalt mixing unit is with replaceable liners, arms and tips. Uniform mixing in short time is possible with the advanced and maintenance free mixer.Weigh scale of asphalt is located just adjacent to the mixing unit. Bitumen from the tanks below is pumped into this weighing unit. After weighing, the bitumen is pumped into the mixing unit for addition into the mixing unit.

- Control panel: The control panel is PLC based and is modern and sophisticated yet user friendly. Control panel is the heart of the equipment. Atlas is one such asphalt plant manufacturers who has developed a simple and user friendly software which is very easy to understand and a pleasure to operate by operator. There are several important commands like setting of each and every critical parameter, setting the batch timings, sizing the batch, taking printouts, etc as a standard package. Optional SCADA type control panel is also available with Atlas.

Complete asphalt Plant comprises of all these units that work in synchronization to make great equipment. Any maintenance free equipment gets its name and fame only after years of consistent performance.

Tower unit:The tower unit consists of three main components like the vibrating screen, hot bins and the mixing unit.

Tower unit:The tower unit consists of three main components like the vibrating screen, hot bins and the mixing unit.