The bitumen drum decanter working principle revolves around the idea of safely melting the bitumen. Once the bitumen is in liquid form the machine will extract/transfer it to the storage or transfer tanks. Asphalt melting units by Atlas are available in capacities ranging from 4 tons, 6 tons, 8 tons and 10 tons. Bitumen filled in the barrel or bags can be melted by this decanting machine.

The liquid asphalt can be used for spraying on the roads prior to laying of hot mix asphalt. This liquid asphalt can be used in an asphalt mixing plant for making HMA. This end product will be used for road construction. It is the best way to safely convert bitumen in liquid form without changing the properties of bitumen. The safe method, reliable design, and environmentally friendly process make this an ideal choice for melting asphalt.

Important specifications of Atlas bitumen decanter are as below:

| Model | ACM-4 | ACM-7 | ACM-9 | ACM-11 |

| Productivity (tph) | 4 | 6 | 8 | 10 |

| Storage | 10 tons | 15 tons | 20 tons | 25 tons |

| Asphalt temperature (º C): | 100-160 | 100-160 | 100-160 | 100-160 |

| Number of drums per batch | 27 drums : 185 kgs. each | 40 drums : 200 kgs. each | 50 drums : 200 kgs. each | 60 drums : 200 kgs. each |

| Total time | 60-70 minutes in continuous operation. | 70 minutes in continuous operation. | 70 minutes in continuous operation. | 70 minutes in continuous operation. |

| Heating system | Hot oil circulation | Hot oil circulation | Hot oil circulation | Hot oil circulation |

| Heating of bitumen stored below | Indirect | Indirect | Indirect | Indirect |

| Thermal capacity of thermal oil furnace (kcal/h): | 500000 | 500000 | 500000 | 700000 |

| Thermal oil temperature (º C): | 200-240 | 200-240 | 200-240 | 200-240 |

Working of Bitumen Decanter Machine – Asphalt Melting Equipment

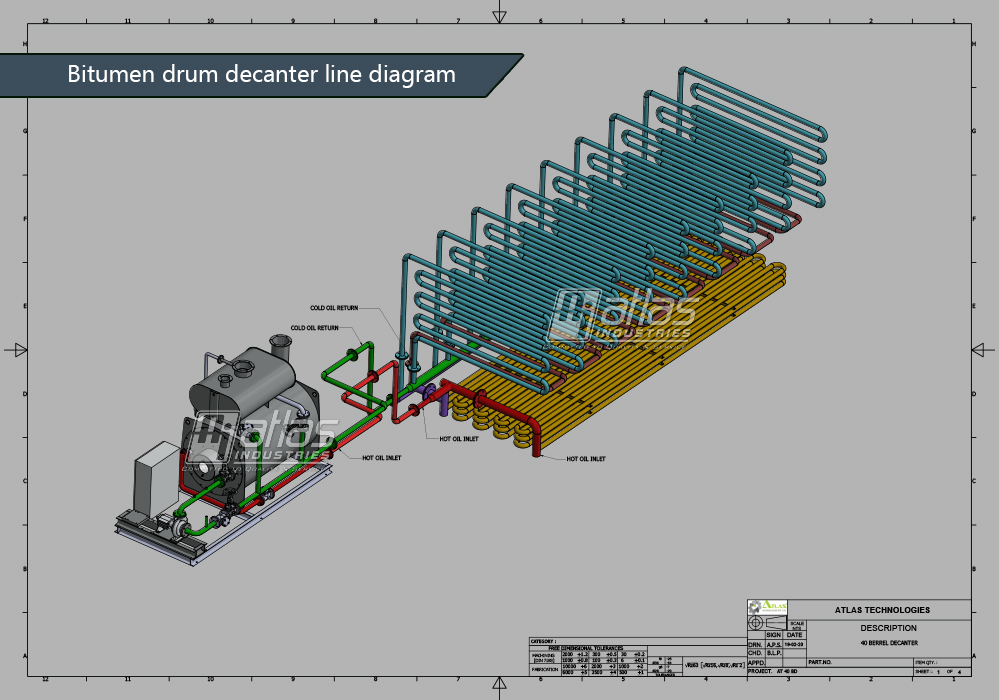

The basic working principle of bitumen drum decanter is to convert solid bitumen into liquid. It is designed to heat and decant drummed bitumen. The heating of bitumen is by hot gases. Hot gases are released by the hot oil that flows through the heating chamber. The bitumen barrels will have their cover removed and placed inverted into the machine by hydraulically operated arms. The bitumen barrels are placed inverted after removal of the top part of barrels. The combination of hot gases and heat transfer oils allows the heat of the chamber and in turn the bitumen barrels inside the chamber. At the bottom, we have sufficient storage space for liquid bitumen. When the bitumen will be melted it will fall down into the storage chamber. The storage chamber is full of heating coils carrying thermic oil. This arrangement allows keeping the bitumen in liquid form as long as the machine is on. Since we now have bitumen stored in liquid form it is very easy to refill the tanks with bitumen. Atlas provides a bitumen pump along with the machine for pumping out the liquid bitumen.

Main components of bitumen drum decanter (melting machine)

Main components of bitumen drum decanter include:

- 3 pass thermic heater

- Heating chamber

However, there are many sub-components that are a part of the main components and important for the functioning of the machine. They are hydraulic systems for loading of bitumen barrels, pipelines for circulation of hot oil, burner for heating the oil, bitumen pump for extraction of bitumen, and control panel for controlling the thermic heating system of the machine.

Main features of bitumen drum decanter – Asphalt Drum Melter

Atlas bitumen drum decanter has many advantages and features. It is an excellent drum melter for an easy and reliable way to melt bitumen at sites. It can be integrated with any Asphalt plant for an uninterrupted supply of liquid bitumen.

- Reliable, efficient, and safe way to melt bitumen.

- Best and economic operation as it utilizes hot air as well as hot oil to melt bitumen.

- It is a proven, maintenance-free design. Fitted with a low noise and efficient diesel burner.

- Thermic oil is a 3 pass system that is more fuel-efficient.

- Ideal for sites where bitumen availability is a problem.

- The indirect heating system by thermic heater does not allow bitumen aging.

- Temperature control is automatic as the desired temperature can be set and maintained.

- The Thermic heater works with diesel as a fuel. The separate fuel tank also provided.

- Optional fuels like FO, LDO, and even wood or gas-fired thermic heaters are available.

- Effortless loading of bitumen barrels by hydraulic arms.

- It can be applied and integrated into any system as it can fill bitumen trucks or bitumen tanks.

- The main unit is fully insulated to cover heat loss.

- Sufficient storage of bitumen below the main unit.

- Bitumen tanks can be supplied and integrated with this unit for additional storage.

- Easy to use the machine – can be operated with some training.

- Easy to install and reinstall. Can be used anywhere easily with little training.

Bitumen drummed decanting machine is an investment that will last for a long time. The Atlas makes asphalt melter from India is with quality and reliable design. The heating is fast, efficient, and safe. The power consumption is less and the fuel used can be customized. The equipment is designed to be used for many years. It is easy to shift sites without hassles. Contact Atlas Technologies Pvt. Ltd. to learn more about the same.