Regular maintenance is essential for the smooth operation of an asphalt batch mix plant, and having a stock of spare parts on hand is a critical component of effective maintenance planning. In this blog, we will explore why maintaining a stock of spare parts is crucial for ensuring uninterrupted operations of your asphalt batch mix plant. We will discuss the benefits of having spare parts readily available, the key components to keep in stock, and how it can help you minimize downtime and maximize productivity.

Benefits of Having Spare Parts Readily Available

Having a stock of spare parts readily available for your asphalt batch mix plant offers several benefits. First, it ensures that you have the necessary components on hand to replace any worn-out or damaged parts quickly, minimizing downtime. This helps you avoid delays in production, project delays, and additional costs associated with prolonged plant shutdowns. Second, it provides flexibility in scheduling maintenance and repairs, allowing you to address issues promptly and efficiently without waiting for parts to arrive. Third, it helps you avoid using substandard or makeshift replacement parts in emergencies, ensuring that only genuine and reliable components are used in your plant, which is crucial for long-term performance and durability.

Key Components to Keep in Stock

To effectively maintain your asphalt batch mix plant, it’s important to keep a stock of spare parts for key components that are prone to wear and tear or are critical for plant operations. Some of the key components to keep in stock may include:

Conveyor belts: These are crucial for transporting aggregates in the plant. Keeping spare belts on hand can help you quickly replace any damaged or worn-out belts, ensuring uninterrupted material handling.

Rollers: The plant makes use of several rollers and having a few of them handy will not make any difference. Different rollers are used in different parts and you can consult your manufacturer to give you a list of the items.

Vibrating screens: Vibrating screens are frequently used and they are the ones subject to maximum torture. Screens are continuously being used and hence they can get damaged due to frequent use. It is advisable to keep a few in stock to avoid last minute problems.

Thermocouple: The plant uses temperature sensing instruments at many places like, drum, screens, hot bins, mixer etc. It is very critical to get accurate and updated reading from all the places. Hence it is very important to keep a few of these instruments handy.

Mixer blades and arms: The mixer is a critical component of the asphalt batch mix plant, responsible for thoroughly mixing the aggregates, filler, and bitumen. Having spare mixer blades and arms on hand allows you to replace them promptly in case of wear or damage, ensuring optimal mixing performance.

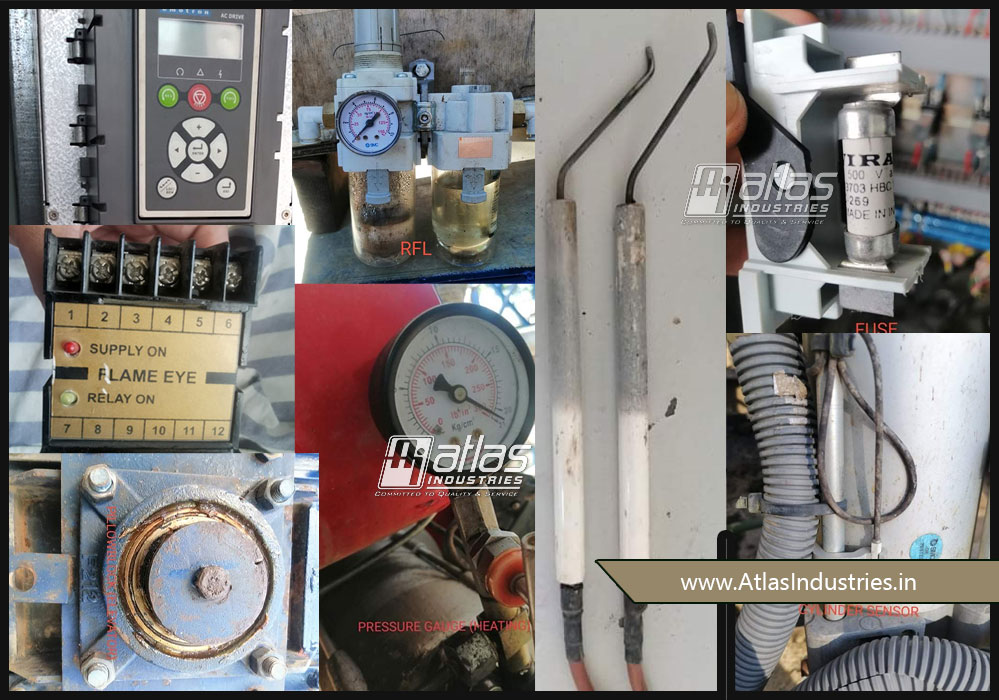

Burner components: The burner is made up of many items like solenoid assembly, flame sensors, ignition transformers, regulating valves, etc. It is very important that these components work efficiently in order to heat the drum unit. Failure in any of the part will cause trouble in operation of the asphalt plant. So it is recommended that sufficient burner spares to be kept in stock.

Bearings: Bearings are used in various components of the asphalt batch mix plant, including the dryer drum, conveyor rollers, and mixer. Keeping spare bearings on hand can help you quickly replace any faulty bearings, preventing further damage and ensuring smooth operations.

Electrical components: The electrical system is a crucial part of the asphalt batch mix plant, controlling various operations and ensuring proper functioning. Keeping spare electrical components such as motors, switches, and sensors on hand can help you quickly address any electrical issues and minimize downtime.

Bag filter: Bag filters are an absolute necessary for keeping the pollution in check, some of the bags can be damaged due to various reasons and it takes time to get the new ones in place. Proper and efficient cleaning of the bags is very important and timely replacement of the damaged or work out bags is also important.

Minimizing Downtime and Maximizing Productivity

Maintaining a stock of spare parts for your asphalt batch mix plant can help you minimize downtime and maximize productivity. With spare parts readily available, you can quickly address any issues or component failures, reducing the time taken for repairs and maintenance. This helps you avoid prolonged plant shutdowns, production delays, and additional costs. By keeping spare parts on hand, you can also plan maintenance and repairs more effectively, scheduling them during periods of low production or downtime, and ensuring uninterrupted operations during peak production periods. Overall, having a stock of spare parts helps you minimize downtime, maximize productivity, and ensure smooth and efficient operations of your asphalt batch mix plant.