The main use of an asphalt mixing plant is to mix bitumen and aggregates at elevated temperature to produce hot mix asphalt. It is widely used for construction of road, pavement, airport, etc. This material is prepared by a batch type or an asphalt drum mix plant. The proportions of the material prepared for each of the application differs. Meaning there is a fix recipe for each of the application to produce the exact required hot mix asphalt for each job work. The recipe is a fix combination of different sizes of aggregates, bitumen and binder material. Aggregates can be of different sizes including dust.

Different types of hot mix plants are as below:

● Batch type – It produces hot mix asphalt in batches.

● Drum / continuous type – It makes HMA in a continuous process.

The common function between both the types is to produce hot mix asphalt from the required mix design. The method varies a lot, but the end product is hot mis asphalt. It should be noted that a batch mix type asphalt plant will produce a better quality of hot mix asphalt. Its process is far better and superior for producing hot mix asphalt compared to a continuous plant. A batch type of asphalt plant is more reliable and sophisticated when the end product is concerned. They are also expensive to own and maintain.

The drum type of asphalt plants will require less initial cost of investment. They also require less space to install. In fact, they are easier to maintain and use. Drum type of continuous asphalt plants are easier to transport and require less civil works for installation. The time taken for installation and start up is much less.

What is asphalt drum mix plant – All about continuous drum mixer

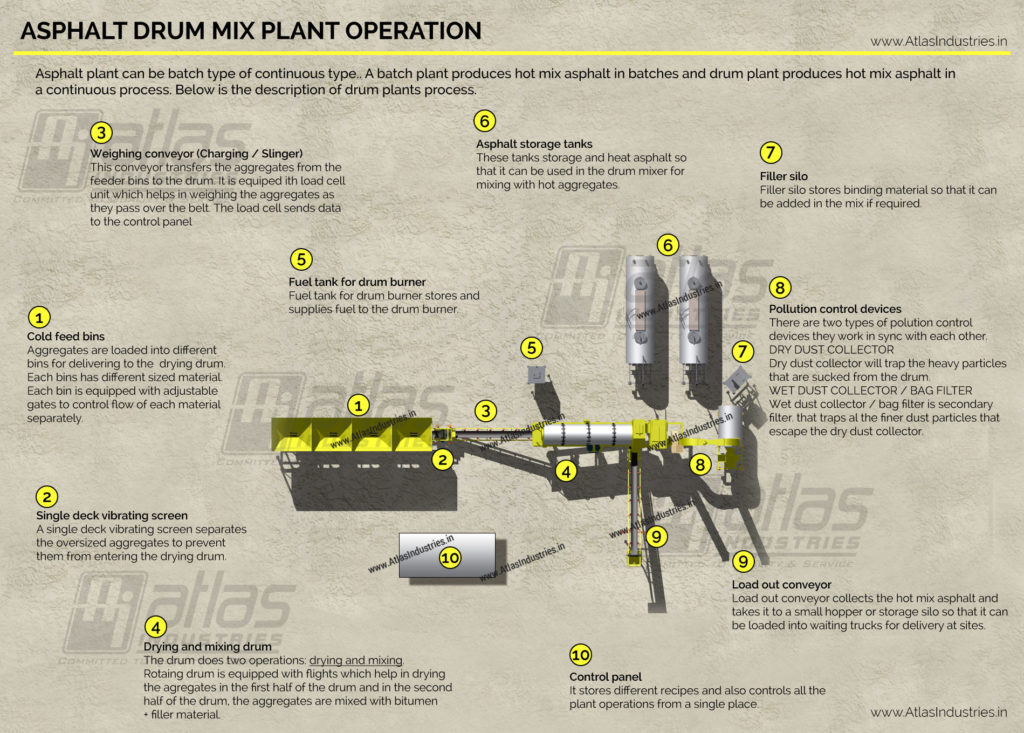

What is asphalt drum mix plant? The question is very common and asked by many people. However, the answer is simple: a drum mix plant is a type of asphalt plant where all the important processes like drying and mixing are done inside a single component – the drum. The process carried out is continuous and hence the name continuous drum mixer. In this equipment, the drum becomes the main component. It is a cylindrical rotating unit which is slightly inclined towards one end.

The starting point of the process of producing hot mix asphalt starts from the feeding of the aggregates in the cold feed bins. The process ends when the hot mix of asphalt starts coming out from the drum. It is worth understanding how this equipment packs so much in a drum to heat and mix all in a quick time process.

If we need to break up the asphalt drum mix plant operation in simple steps it has to be as per below:

● Feeding of the aggregates into individual cold feed bins. The aggregates have to be fed into separate bins as per their sizes. Each of the bins is synchronized to get the desired controlled flow of each aggregate.

● Once the aggregates exit the bin, they will be falling into a conveyor below the bins. This conveyor will transfer the aggregates into the charging conveyor.

● Before getting transferred to the charging conveyor, all the aggregates will move through a vibrating screen. This single deck screen will ensure that the oversized materials are removed.

● Once the aggregates are getting transferred through the drum from the charging conveyor they will be collectively weighed. This part is important as this weight data will be sent to the control panel for synchronizing the flow of bitumen and biner material.

● The aggregates upon entering the drum are treated to heat coming from the burner system. This first part of the drum is for evenly heating the aggregates. Once the aggregates are heated they will be ready for coating with bitumen.

● The drum unit is inclined at the other end to facilitate the onward movement of the aggregates to wards the discharge end.

● Bitumen is stored in separate tank. These tanks are equipped with a burner system for keeping the bitumen in liquid condition making it ideal for the bitumen to flow. Once the signal is received from the control panel, bitumen will be following in the set quantity into the drum unit for mixing with the hot aggregates. The flow of bitumen is controlled by a variable speed drive motor.

● Filler is an important component which is added to the mix material along with bitumen. We provide a compressor for addition of filler material into the drum.

● Once the materials are homogeneously mixed, they will be transferred into a conveyor and then into waiting trucks. In some cases we can also provide hot mix storage silos for temporary storage of the mix material prior to the discharge.

● A control panel unit is also one of the most important components. It will control all the components to ensure that the proportion of all the materials used is as desired. Control panel also gives out all important date like material uses, recipe storage, recipe design addition, mix material data, etc. all in a printable format.

What are the components of an asphalt drum mix plant?

Atlas make asphalt drum mix plants have many components, they are designed to work in synchronization. This will ensure that the best quality of hot mix asphalt is produced. The synchronization of all these parts of the drum mixer asphalt plant is important to ensure optimum result.

Main components of the asphalt drum mix plant are as below:

● Cold aggregate feeder bins

● Slinger / charging conveyor with load cell

● Drying and mixing drum with burner

● Load out conveyor

● Bitumen tanks

● Mineral filler unit

● Control panel

Drum asphalt plants usually occupy less space compared to a batch type asphalt plant. A standard drum asphalt plant will occupy space of 45-55 sq. m. including space for sufficient storage of raw material and bitumen.

Types of asphalt mixing plants

We can categorise asphalt mixing plants into two types: batch type and continuous types. They can also be categorised into:

● Stationary type of mixing plants

● Mobile type

Stationary mixing plants are for those customers who want to produce hot mix asphalt only at a single place. Stationary plants will be higher in capacity. They will be with bigger sized components and structures, more suited for long term production without moving often. Mobile type of asphalt mix plants is preferred for producing medium to small quantities of materials which is also having the option to move different places. A mobile plant may be stationed at a place and then moved to another site frequently. They will usually be easier to set up and run-in quick time.

Atlas Asphalt drum mix plants are very easy to maintain and own. They come with easy to use control panel with tough display. The real advantage that they have is its smaller size compared to the batch machines. They can be towed easily and set up in a few days. It’s even easy to transport them across continents due to its compact size and containerized design.

Contact Atlas Industries to learn about how we can help you with buying an asphalt plant.