- Overview

- Components

- Photo Gallery

- Video gallery

- Download

- Request a quote

Overview

Modular asphalt batch plant from leading Indian manufacturer of mix type asphalt plants. We are looking to export asphalt batching plant to Sri Lanka, Nepal and Nigeria. Now available in capacities 80 tph, 120 tph, 160 tph, 200 tph and 260 tph. Store, edit unlimited recipes on PLC panel. Cost-effective machine with low running cost and lowest cost of spare parts. More than 65 installations in 3 years. Tried and tested design for ultimate performance.

Atlas Industries offers asphalt batching plant for sale. We have developed this equipment to help contractors produce hot mix asphalt using a discontinuous process with the help of accurate weighing technology coupled with fast, low maintenance and reliable mixer.

Asphalt Batch Plant Operational And Maintenance Cost

Atlas has made sure that operating and maintenance cost of its asphalt batching plants is lowest. The main aim is to develop a design that allows customers to have a low price equipment that allows peace of mind. Contact us to know how we can help you lower your overall cost and maximise your return on investment.

Atlas manufactured asphalt batch mixing plant for sale has many advantages over the competition. It is a simple-to-use machine which is designed to perform with low maintenance. The structure is heavy and suited for rough applications. Precise weighing ensures that customer gets his job done with precision. Some of the advantages are as:

- Basic plant structure is strong.

- Containerised design reduces transportation cost.

- Tower unit is mounted on skid plates. It helps in quick installation. Other units like cold feeders, drum unit, etc. It is supplied with skid mounting.

- Burner is low noise, high efficient and multi fuel.

- Low maintenance and low operating cost is the highlight of this asphalt batch mixer from India.

- Drying drum is thermally insulated.

- The pairing of burner and drum is perfect which allows heating of aggregates evenly in short time after spending less fuel.

- All units are modular. This helps to reduce installation and transportation time.

- Total seven pneumatic cylinders are used. The size of each cylinder is same allowing to keep less stock.

- Bitumen weighing and transfer system is simple and maintenance free. We are using only one bitumen transfer pump to transfer bitumen.

- Mixing unit gear boxes are planetary type. They are directly mounted on each shaft. This allows better torque absorption.

- The cylinders are easily accessible and hence maintenance is easy.

- Less civil work is required at site.

- Bag filter unit is more efficient. It has total of three rotors at the top which makes cleaning efficient.

- The control panel is equipped with standard components.

- The PLC panel comes with easy to use software and colour display. It is as easy as operating a mobile phone.

- Vibrating screen sizes can be customised to suit customers requirement.

- Each unit of the tower has sufficient space for maintenance.

- It is also possible to supply this with wet dust collector instead of bag filter.

- We have kept the cost of spare parts the lowest in the industry.

- Various hot mix recipes can be stored in the panel and can be changed easily with few clicks.

Asphalt Mixing Plant - Hot Batching Plant

Get Asphalt Batch Mix Plant for sale from leading exporter, supplier of hot mix plant. Asphalt batch plants from Atlas is available for sale with advanced touch screen PLC panel. Available in modular design for fast assembly and installation. If you are looking for a reliable equipment manufactured by a reputed manufacturer with years of manufacturing experience of construction equipment, then ATLAS is the answer. We offer not only reasonably priced Asphalt Mixing Plant but also promise a tension free and clean performance.

The components are: cold aggregate feeding system; counter flow drying drum with multi fuel burner; elevator system for conveying hot aggregates to the vibrating screen, batch tower unit comprising of four deck vibrating screen; separate weighing bins for aggregates; separate weigh hoppers for bitumen and for mineral; pug mill type mixing unit below the aggregate weighing unit;& primary and secondary pollution control devices which work in sync with each other; asphalt storage & heating tanks and PLC control panel inside the control cabin.

The spare parts are also reasonably priced by us so that you can keep and use this equipment for years to come, not need to change equipment frequently with each project.

Below is the tower of asphalt plant by Atlas Industries.

Component wise details you will find in the COMPONENTS TAB above.

Components

Aggregate feeders & vibrating screen

Cold feed bins are with variable speed drive motors for each bin allowing to control individual material as required.

Primary vibrating screen is single deck for oversize material removal before the aggregates enter the drying drum.

Drying drum

Drying drum of asphalt batch plant is designed with flight design that help in lifting the aggregates so that they get heated evenly before they exit the drum. Drying of aggregates takes place in the drying drum making the process fuel efficient. Even raw materials with high moisture content get dried easily. Insulated drying drum helps to retain heat and save energy.

Burner

Modulating burner is designed for low fuel consumption, low noise and easy maintenance. The burner is capable of running on diesel or LDO (Optional: FO).

Burner size and drum rotation speed is coupled with efficient flights. This allows maximum output of the burner while simultaneously reducing the fuel consumption.

Dry dust collector

Correct sized dust collector is the key to the success of the asphalt mixer. The plant is supplied with cyclone type dry dust collector.

Dust laden gas passes through the dry dust collector where they are cyclonically treated to settle the heavier dust. Excess dust from the vibrating screen and hot bins are also sucked by the dry dust collector.

Bag house filter

Bag house works in combination with the dry dust collector. It is one of the most effective pollution control device available today.

Venturi type wet dust collectors are also available.

Bitumen tanks

Fully insulated tanks available in various capacities.

Asphalt tanks are with direct or indirect heating and With hot oil jacketed piping.

Hot elevator and mineral filler hopper with elevator

Hot elevator is for taking the dried aggregates to the top of the tower for screening. Hot elevator is fully covered and with anti-slip feature.

Filler hopper is for addition of minerals to the hot mix. Filler is conveyed to the filler weighing hopper by a bucket elevator.

Vibrating screen

Four deck vibrating screen is for separation of four types of aggregates and removing oversized aggregates. The screen is powered by strong vibrating motors allowing vibration in circular motion. The screen of asphalt plant is designed for free flow of the material.

Large platform across the screening unit makes access to screens easy. Maintenance and screen replacement can be done in quick time. Screen sizes can be customised.

Hot aggregates bin

Hot bins have compartments to store aggregates separately after they are screened by the vibrating screen. These hot bins store the aggregates for a short period of time till they are weighed.

Weighing for aggregates

Weighing system is separated in such a way that it is not affected by the vibrations from the vibrating screen. Aggregates are discharged one by one by the weighing system into the twin shaft mixer for mixing.

Weighing for minerals

Weigh hopper for filler is mounted on three load cells with pneumatic cylinder for quick discharge. It is free from vibrations from the vibrating screen.

Weighing for bitumen

Bitumen is weighed in a weigh hopper which is suspended on 3 load cells.

Mixing unit

Mixers manufactured by Atlas are designed for homogeneous mixing in short time.

Mixer is fitted with long life and easy replaceable Ni-Hard liner plates and tips.

Strong shelled body is insulated by hot oil jacketing from all sides. This mixer is with synchronized drives on each shaft. Quick maintenance is possible by easy access to the maintenance doors.

Discharge gate runs through the entire length of the mixer allowing quick discharge of the hot mix material.

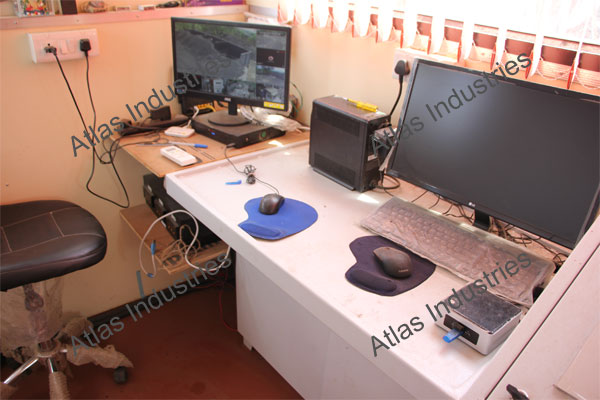

PLC control system

The software of PLC control panel is developed in house. It is keeping in mind that the operation of asphalt batch mix plant has to be easy.

Colour display on HMI allows to read information easily.

Control panel is designed for easy maintenance.

Photo Gallery

Video Gallery

260 tph hot asphalt mixing plant

Operation of asphalt batching plant

180 tph asphalt batch plant

3D video asphalt batch mix plant

See 3D video of Atlas asphalt batch mix plant.

Asphalt batch mix plant in Pune Municipal Corporation

See video of 120 tph Atlas asphalt batch mix plant installed and working in Pune Minicipal Corporation.

80 tph asphalt plant in Myanmar

See video of 80 tph asphalt batch mix plant installed in Myanmar. The machine is featured with skid plates for all important components and all units are pre wired to reduce the installation time at site.

160 tph batch plant in Jaipur

View video of 160 tph batch plant installed in Jaipur, India. See full and detailed video of equipment working.

Batch asphalt plant India

New design asphalt batch mixer plant from Atlas. The plant features containerized design modified to lower the transportation costs and also boasts of lower maintenance cost therby increasing operational efficiency.

Control panel of asphalt batching plant

See detailed video of the control panel of Atlas asphalt plant.

Tower asphalt plant 120 tph

See video of tower asphalt plant of capacity 160 tph. Built on a sturdy frame this plant is designed to operate in rough conditions.

Asphalt batch mix plant

Asphalt batch mix plant of 120 tph manufactured, sold and installed by Atlas Industries near Bhatinda, India.

Our plants are desgned for rough Indian applications, low maintenance, low operating costs. Spare parts are resonably cheap compared to the competition.

Hot mix asphalt plant - 160 tph

Atlas hot mix asphalt plant of 160 tph installed near Ahmedabad, India. This plant is equiped with natural gas burner for drying drum and also for the hoit oil heater. Hot oil heater is for indirect heating of bitumen tanks and for jacketing the mixer. Bga filter is provided for keeping the dust emission low. Customer opted for two bitumen tanks. Atlas PLC control panel with user friendly software is best for operation of the asphalt plant.

Batching plant - 160 tph

Batching plant of capacity 160 tph installed in Dahod, India. This equipment is batch type and has provision for separate weighing for four aggregate types, minerals and bitumen. The plant comes with cyclone type dry dust collector and bag filter for maximum pollution control.

Control panel is PLC touch screen for easy operation. Customer opted for two bitumen tanks: one with direct heating and one with indirect heating.

120 tph tower asphalt plant

Atlas 120 tph tower asphalt plant installed near Radhanpur, India. Plant is supplied with four bin feeder unit, conveyor, drying drum, two bitumen tanks, dry dust collector, bag filter, PLC control panel and tower unit consisting of hot elevator, mineral feeding system, vibrating screen, hot bins and mixing unit.

Asphalt batch plant

Plant supplied with cold feeding bins, conveyor, drying drum with burner, aggregate and filler elevator, dry dust collector, bag house, two bitumen tanks with indirect heating system, batching tower comprisinng of vibrating screen, hot bins and mixing unit. Control panel is PLC type with printing facility.

Asphalt batch mixing plant

Asphalt discontinuous plant is available in capacities 80 tph, 120 tph and 160 tph. Capacities above 160 tph are tailor made.

Seen here is plant of 80 tph with PLC control panel and venturi type wet dust collector unit.